DIY vs. Professional Spray Foam Insulation: Which Is Right For You?

September 15th, 2023

7 min read

Doing things yourself can be very rewarding. Whether you take pride in a good result or enjoy saving money, DIY projects are often great options for handy and price-conscious homeowners. As you've researched insulation options, you've discovered that spray foam can be a DIY product. You want to know whether a professional contractor or DIY spray foam will be your better investment.

South Central Services has installed spray foam insulation in hundreds of homes around Shippensburg, Pennsylvania. Some of those projects have included cleaning up DIY jobs gone wrong. We hate to see customers lose time and money on a product that didn't give them what they needed.

DIY spray foam has its place in home improvement projects, but it is not always the right choice. The goal is an effective spray foam insulation solution, no matter how you arrive there. This article gives a transparent comparison of DIY spray foam insulation and professional contract work.

By the time you finish reading, you will know:

- Which method will cost more

- Which method takes longer

- Which method delivers a better product

- Which method poses more risks

- When it is best to use DIY spray foam kits

Don't have time to read right now? Check out everything you need to know at a glance.

Which Is More Expensive: DIY Or Professional Spray Foam?

One reason you may be considering DIY spray foam insulation is the cost of spray foam. Spray foam insulation is expensive! So, can you save money on spray foam by installing it yourself?

By comparing the three key areas of cost, we can determine if DIY spray foam is more affordable. These areas include:

- Raw material costs

- Labor costs

- Unforeseen costs

Let's examine each of these in more detail.

1. Raw Material Costs For Spray Foam Are Approximately The Same.

If you compare the raw materials costs of DIY kits and professional contractors, the prices are approximately the same.

For both methods, the price can range. DIY kit price depends on the kit size and whether it is on sale. Rates for raw materials vary by contractor.

When we broke down the cost per board foot of DIY kits available online, the price was within our range of pricing for spray foam insulation. A standard DIY kit from a home improvement store costs approximately $400 and covers 200 board feet. The cost would be $2 per board foot.

2. You Can Save On Labor Costs, Depending On Project Size.

You will not incur labor costs if you install spray foam insulation yourself. However, it is worth considering whether the cost of labor is cost-effective due to the size of your project.

At what point is the job size worth hiring a professional for?

Which option is more cost-effective will depend on the size of your project. Many contractors have a minimum project cost because traveling with their equipment incurs fixed costs. A small project may need higher material costs to justify paying for a contractor's travel and labor.

As a general rule, projects requiring only one DIY spray foam kit can see cost savings compared to hiring a professional. Projects that require more than two to three kits of DIY spray foam should consider contacting a professional contractor.

3. DIY Spray Foam Includes Unforeseen Costs.

A quote from a professional contractor should disclose all costs associated with your project. However, DIY spray foam kits may require additional purchases.

DIY spray foam kits do not include all the equipment necessary for safe installation. Your purchase of a DIY kit will provide installation equipment but no personal protective equipment (PPE).

You may already own some of the PPE needed, like safety glasses, gloves, and disposable coveralls. It is highly unlikely that you own a respirator with the correct cartridge. Acquiring this type of equipment will cost at least $100.

Additionally, you may want to invest in optional equipment to maximize product quality. Because DIY kits only include spraying tools, it can be difficult to maintain or monitor vital information like temperature, ratio, and pressure.

Which Method Takes Longer: DIY Or Professional Spray Foam?

Anyone who has lived in the midst of construction understands time investment. Whether you've waited for a new build home to be completed or lived through construction zones from home upgrades, these things can take time. Things being left unfinished can feel quite frustrating, whether you're working on your own or have hired a professional.

You can understand the time you invest in spray foam as passive time and active time. Passive time would involve more research- or calculation-based activities, while active time would involve physical activity.

How much passive and active time do these spray foam methods require?

1. Both Methods Require Investing Passive Research Time.

Both DIY spray foam and hiring a professional contractor can involve investment in passive time. No matter which route you take, you will need to research your options.

You will spend time researching and selecting your kit if you choose the DIY route. If you hire a professional, your primary time commitment will be researching contractors. This passive research time is vital for both methods to ensure you choose the right option. Choosing the right size kit or the right contractor is an excellent use of your time.

2. DIY Spray Foam Requires Significantly More Active Time Investment.

If you choose DIY spray foam, you will have a significant active time investment. You will have to take measurements of your space for calculations and physically install the foam. Depending on the size of your project, your active time could be as short as an evening or as long as several weeks.

If you work with a professional, you may also have some active time. This active time will vary by the type of project. An example would be hiring a professional to reinsulate your attic. The contractor may offer you some cost savings by having you remove existing attic insulation before they arrive.

Which Product Has Better Quality: DIY Or Professional Spray Foam?

Knowing that the raw material costs for spray foam are universal, you want to be sure that the DIY foam you purchase will be the same quality as professional foam.

Let's compare the raw material quality and the finished product quality.

1. Raw Material Quality Is Essentially The Same.

The raw materials of DIY kits and professional grade 55-gallon drums are of the same quality. The chemical makeup of the raw chemical components is essentially the same.

2. DIY Spray Foam Does Not Offer Comparable Finished Product Quality.

Spray foam insulation is like a science experiment. In any science experiment, too many variables will change the outcome. For spray foam, the key variables are temperature, pressure, and ratio. Changes to any of these variables will alter the finished product.

DIY spray foam kits come with basic equipment to successfully create spray foam. These kits provide the raw chemical components in equal amounts, a spray hose, and several spray nozzles.

While this DIY equipment can spray the foam, it cannot maintain and monitor the variables of the spray foam chemical reaction like a spray foam rig.

.jpg?width=440&height=400&name=Labeled%20Rig%20(3).jpg)

Professional contractors invest anywhere from $60,000 to $100,000 in their spray foam rigs. These trucks and trailers are filled with equipment that keeps these variables in check. The equipment also optimizes these variables for consistent and high-quality foam.

If we start with the same ingredients for our chemical reaction, then the result will depend on the process. While DIY spray foam kits have the same components as professional-grade foam, the equipment provided cannot create a finished product of the same caliber.

Are There Health Risks With DIY Or Professional Spray Foam?

You should know about two potential health hazards related to installing spray foam: off-gassing fumes and off-ratio foam. Anyone considering DIY spray foam installation should be educated about these risks and how to avoid them.

Let's look at these two risks in more detail.

1. Off-Gassing Fumes Are Part Of The Manufacturing Process.

The chemical reaction to create spray foam releases a byproduct called off-gassing. Off-gassing is a normal and expected part of the chemical reaction but should not be inhaled. Foam installers wear personal protective equipment (PPE) to avoid inhaling these toxic fumes during installation.

Professional contractors require all residents and pets to vacate during installation to protect them from off-gassing fumes. If you hire a qualified professional, you should not be exposed to any off-gassing fumes.

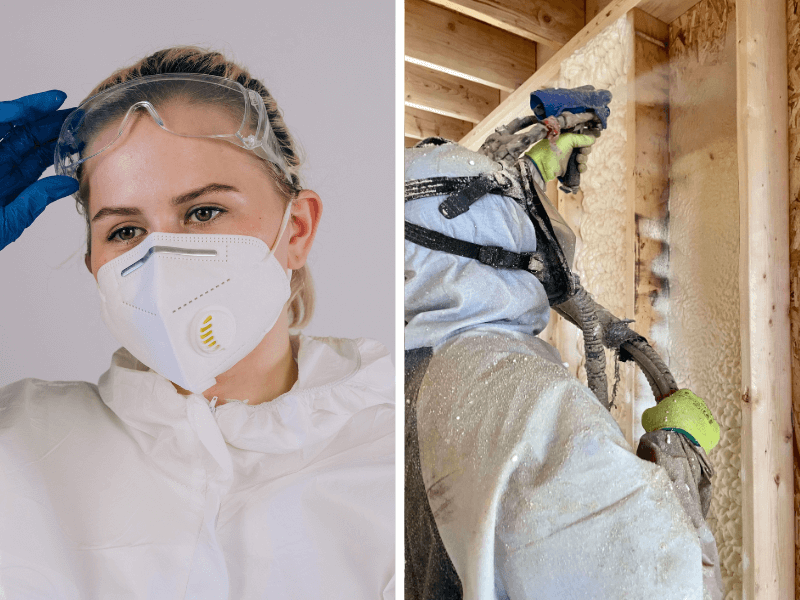

If you choose the DIY route, you will be the installer. You must invest in the appropriate PPE to protect yourself, just like professional contractors do.

DIY spray foam kits do not come with PPE, even though this equipment is essential for safety. The bare minimum equipment you must acquire includes a respirator with the appropriate cartridge, full disposable coveralls, gloves, and eye protection. More PPE may be needed.

DIY spray foam kits do not come with PPE, even though this equipment is essential for safety. The bare minimum equipment you must acquire includes a respirator with the appropriate cartridge, full disposable coveralls, gloves, and eye protection. More PPE may be needed.

Consult the manufacturer of the DIY kit you purchase for detailed information about what equipment you need.

2. Off-Ratio Foam Is A Failed And Ineffective Spray Foam Product.

Off-ratio foam is a type of failed spray foam insulation. Off-ratio foam is one of the most dangerous because it can result in continuous off-gassing. While off-gassing is a normal byproduct of a chemical reaction, an effective product will stop off-gassing when the chemical reaction is complete.

For off-ratio foam, some amount of chemical remains. This chemical is in its raw state and can off-gas indefinitely.

Professional contractors are trained to know the signs of off-ratio foam and can recognize and remove it. Off-ratio foam is always the result of equipment malfunction.

Since the equipment in DIY spray foam kits is rudimentary, DIY foam is more likely to go off-ratio. Homeowners can also struggle to recognize the signs of off-ratio foam because they are not as familiar with spray foam.

DIY Spray Foam Requires More Personal Responsibility From You.

When you install spray foam insulation yourself, you are responsible for every aspect of the installation. You must determine square footage calculations, board feet estimates, and the number of needed kits.

If something goes wrong with DIY spray foam, no insurance will cover you. You cannot get your money back. If the spray foam was off-ratio, you must also pay for its removal and replacement. Leaving failed DIY foam in your home can pose health risks.

Personal responsibility lessens considerably by hiring a qualified contractor. As the homeowner, you are responsible for working with the contractor to schedule their work time. You must also comply with leaving the premises during application. Other than these basic things, there is no responsibility on you.

If a professional contractor makes a mistake during your installation, you will not bear the financial cost. Contractors are insured and can be held responsible for any foam failure related to their work or the sprayed product.

When Is DIY Spray Foam Insulation The Right Solution?

We recommend DIY spray foam insulation as a relatively inexpensive air-sealing tool for small projects. DIY spray foam can be useful for air-sealing if the chemical reaction occurs successfully and on-ratio.

Some examples of small air-sealing projects could include the basement band boards and around the attic's HVAC or electrical penetrations.

In any other case, we cannot recommend DIY spray foam kits.

If these kits provided the monitoring and control necessary to ensure an effective product, we could feel comfortable recommending these for other uses.

Unfortunately, the potential for product failure is so high that these DIY kits often waste time and money. They can also create additional headaches if you need to remove the failed product they created.

The Bottom Line About Choosing Professional Or DIY Spray Foam

DIY spray foam kits can be a simple solution for capable homeowners with small projects. As the scale of a project increases, the potential for disaster from a DIY spray foam kit also increases. The most significant drawback of a DIY kit is its lack of equipment. Between missing PPE and cheap application tools, these kits are likely to backfire.

You are likely concerned with your spray foam solution's safety, longevity, and effectiveness. If your project requires more than a single DIY kit, you will want to contact a professional contractor for a quote. By working with a professional, your insulation is insured and will be installed with premium equipment. The variables in the chemical reaction to create the foam make all the difference.

Now that you have compared DIY spray foam to a professionally-installed product, your next step is to:

- Learn how to evaluate contractors in your area to find a qualified professional

- Confirm whether you could save money by installing spray foam yourself

- Estimate the cost of professional spray foam insulation for your project

Disclaimer: While we strive to publish information accurate to building science, local building codes and standards supersede our recommendations.

Alexis has been fascinated by spray foam insulation since 2018. When she isn’t thinking about insulation, Alexis is geeking out over storytelling and spreadsheets.

Topics: