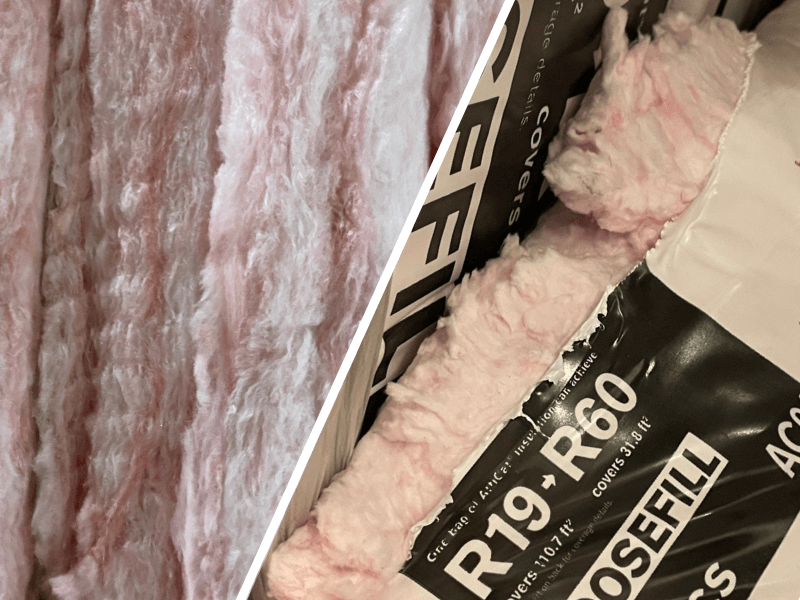

Fiberglass: Batts vs. Blown-In Insulation

October 9th, 2023

6 min read

You're leaning towards fiberglass insulation for your home improvement project and want to know which is better: batts or blown-in. Is one form of fiberglass more affordable than the other? Are both types of fiberglass easy to install?

South Central Services specializes in spray foam insulation, but we install fiberglass batting and blown-in in the appropriate applications. Whether or not you should use batt or blown-in insulation will depend on the application. This article will take a deep dive into fiberglass options so you can determine if fiberglass is suitable for your project and, if so, which version to use.

By the end of this article, you will know:

- How much fiberglass batts and blown-in cost

- How easy fiberglass batts and blown-in are to install

- What performance you can expect from fiberglass batts and blown-in

- How long fiberglass batts and blown-in are expected to last

- When (and when not) to use fiberglass insulation

Don't have time to read right now? Check out everything you need to know at a glance.

Price Of Fiberglass Insulations

When you research the prices of blown-in fiberglass and fiberglass batts, it may be difficult to tell which is the better deal. You will come across terms like cost per square foot, R-value, kraft facings, and pallet pricing. How do these factor into price? Which insulation is less expensive?

Fiberglass Batts Cost

Fiberglass batts are marketed by their R-value. The beginning of any fiberglass batt listing should say something like R-15, R-19, or R-38. If you're interested in installing insulation, the first detail you need to know is the required R-value of the place you are insulating.

The necessary R-value will vary by application and geography. For example, if you are insulating an attic in southern Pennsylvania, R-values must be a minimum of R-38.

The cost per square foot for fiberglass batts should be accurate. For example, $100 of fiberglass batt insulation advertised to insulate approximately 40 square feet would cost roughly $2.50 per square foot. A quick search on a home improvement website will show that fiberglass batt prices can vary by as much as $0.60 to $2.50 per square foot.

Generally, the higher the R-value, the more expensive the batting.

Do kraft facings impact price? Fiberglass batt insulation with facings may be more expensive than unfaced batts. However, if your application requires a vapor barrier, you cannot cut costs by skipping the facing. Facings are vapor retarders to help handle moisture content in the air and prevent molding.

Blown-In Fiberglass Cost

Loose-fill fiberglass is generally sold in bags of approximately 28 pounds. How much insulation you will need depends on the necessary R-value of your project. You may see a listed cost per square foot if you shop for loose-fill fiberglass for blown-in applications. However, projects that require higher R-values will have a higher cost per square foot.

For example, let's say you purchase a 28.5 lb bag of loose-fill fiberglass for $60. It is advertised to cover over 100 square feet, giving it a cost per square foot of $0.60. If your application only required an R-value of R-19, this would be an accurate cost per square foot. But your application requires a minimum R-value of R-30, changing the maximum square footage to 65. Suddenly, your per unit cost has jumped to almost a dollar.

Blown-in fiberglass also requires renting a blowing machine to disperse the loose-fill fiberglass particles.

You can expect to spend anywhere from $2.50 to $4.00 per square foot in addition to the blower rental fee. Rental costs can be as high as $200 per day, and some machines require purchasing a particular brand of fiberglass to rent. You should check any requirements of the machine before purchasing your bags of loose-fill fiberglass.

Ease Of Installation For Fiberglass Insulations

How simple would it be for a homeowner to install fiberglass on their own? Whether installing batts or blown-in, homeowners must invest in personal protective equipment (PPE). This PPE includes eye protection, a mask, and gloves.

You may see images of people installing fiberglass without gloves in marketing materials. Not wearing gloves is dangerous and risks embedding tiny shards of glass into your hands.

Blown-in fiberglass is more complicated to install than batts. Calculating how many batts you need for a space is easier, and batts also do not require any equipment rentals. Blown-in fiberglass will require some calculations to determine how many bags you need to purchase, in addition to the rental of a blower.

Performance Of Fiberglass Insulations

Both blown-in and batts are effective at dampening sound transfer. But how well does fiberglass insulate? One of these products is more effective than the other. Let's examine this in more detail.

Fiberglass Batts Performance

Fiberglass batts are one of the lowest-performing insulation products available. While fiberglass batting is inexpensive and convenient to install, the premanufactured shape of batts can cause gaps. Imagine you have a 17-inch wide cavity, but the fiberglass batts are only as wide as 16 inches. If the fiberglass cannot completely fill an empty space, it cannot offer maximum performance.

The maximum performance of fiberglass still does not compare to more expensive insulations like spray foam. Fiberglass allows air to pass through it, slowing conductive heat transfer. Since fiberglass cannot stop airflow or infiltration, anything traveling through the air can enter a home: including temperature differences, allergens, dust, and moisture.

The maximum performance of fiberglass still does not compare to more expensive insulations like spray foam. Fiberglass allows air to pass through it, slowing conductive heat transfer. Since fiberglass cannot stop airflow or infiltration, anything traveling through the air can enter a home: including temperature differences, allergens, dust, and moisture.

Blown-In Fiberglass Performance

Blown-in fiberglass is the higher-performing fiberglass insulation option. Because blown-in fiberglass is a loose-fill product, it can conform to unique spaces and crevices. The gapping problems of fiberglass batts are solved with blown-in fiberglass.

Unfortunately, because blown-in fiberglass is such a light product, it cannot capitalize much on its ability to fill crevices. Cellulose is a heavier blown-in product with a higher performance due to its weight and density. Blown-in fiberglass is fluffier than a batt and still has no air-sealing technology. Loose-fill fiberglass allows air to infiltrate, which hurts its insulating performance.

Longevity Of Fiberglass Insulations

If you want to use a budget insulation like fiberglass, you need to know how long the investment will last you. Understanding a product's lifetime can help you plan maintenance or replacement costs.

Fiberglass Batts Longevity

You will often see fiberglass batts advertised as having a lifespan of a century. This lifespan may be possible for batting if undisturbed and facing no outside variables. In real-world applications, however, fiberglass batt performance may deteriorate within fifteen to twenty years.

%20(T)%20(1).jpg?width=533&height=400&name=7.25.24%20Fiberglass%20Batt%20(garage)%20(T)%20(1).jpg)

Fiberglass batts can sag over time, creating gaps that compromise performance. Other problems, such as dust or mold growth, can occur if the installation area experiences a lot of moisture or air infiltration.

Blown-In Fiberglass Longevity

Blown-in fiberglass, like fiberglass batts, should be checked every fifteen to twenty years. While blown-in insulation may not face problems like potential mold growth or sagging, blown-in insulation products do settle over time. To keep consistent performance levels, blown-in fiberglass will need to have additional insulation installed over the top.

If you choose blown-in fiberglass insulation, check the settling amount to calculate the required R-value. The depth of the insulation will determine the R-value it has settled to. You will also need to rent another blower machine to top off your insulation.

When Should I Use Fiberglass Insulation?

The best application for fiberglass batts is interior walls. Fiberglass batts often create gaps that compromise their insulating value. However, interior walls do not need seamless insulation like other applications in the home. Fiberglass batts are an inexpensive insulation solution. Installing fiberglass batts in your walls can also dampen sounds from room to room.

.jpg?width=533&height=400&name=Spray%20Foam%20vs%20Fiberglass%20Title%20Image%20(1).jpg)

The best application for blown-in fiberglass insulation is attics. However, we must add the caveat that blown-in fiberglass in the attic needs to be paired with an air-sealing product. Before adding blown-in insulation to your existing attic insulation, consider removing the insulation to add an air-seal.

Air-sealing will boost the performance of the insulation by offering something it cannot: stopping the flow of air and the heat that travels with it.

When Should I Not Use Fiberglass Insulation?

We cannot recommend fiberglass insulation for exterior walls or basements. As discussed above, fiberglass insulation is a lower-performing product with no air-sealing capabilities.

For exterior walls, the performance of your insulation is crucial. Those walls create the barrier between the outside world's temperatures and your home's conditioned temperature.

Fiberglass insulation can never be recommended for basements because of its lack of vapor barrier. While some fiberglass batts have kraft facings to act as vapor retarders, below-grade applications like basements can only use products with vapor barriers. The moisture content in below-grade applications necessitates products like closed cell spray foam.

The Bottom Line About Blown-In Fiberglass and Batts

Fiberglass has its place in the insulating world. While not a high-performance product, both the blown-in and batt versions of fiberglass are products that homeowners can install themselves. Given their performance limitations, the best uses for these products are interior walls and attics treated with an air-sealing product.

If your project does not fall into one of these categories, we recommend looking into other insulation options. While you may spend more money on premium insulation, you will save more on your energy bills for the lifetime of your building.

Now that you know the differences between types of fiberglass insulation, your next step is to:

- Compare fiberglass batts and spray foam insulation

- Compare blown-in fiberglass and spray foam insulation

- Review the pros and cons of attic insulation options like fiberglass

Disclaimer: While we strive to publish information accurate to building science, local building codes and standards supersede our recommendations.

Alexis has been fascinated by spray foam insulation since 2018. When she isn’t thinking about insulation, Alexis is geeking out over storytelling and spreadsheets.

Topics: